Your Position:

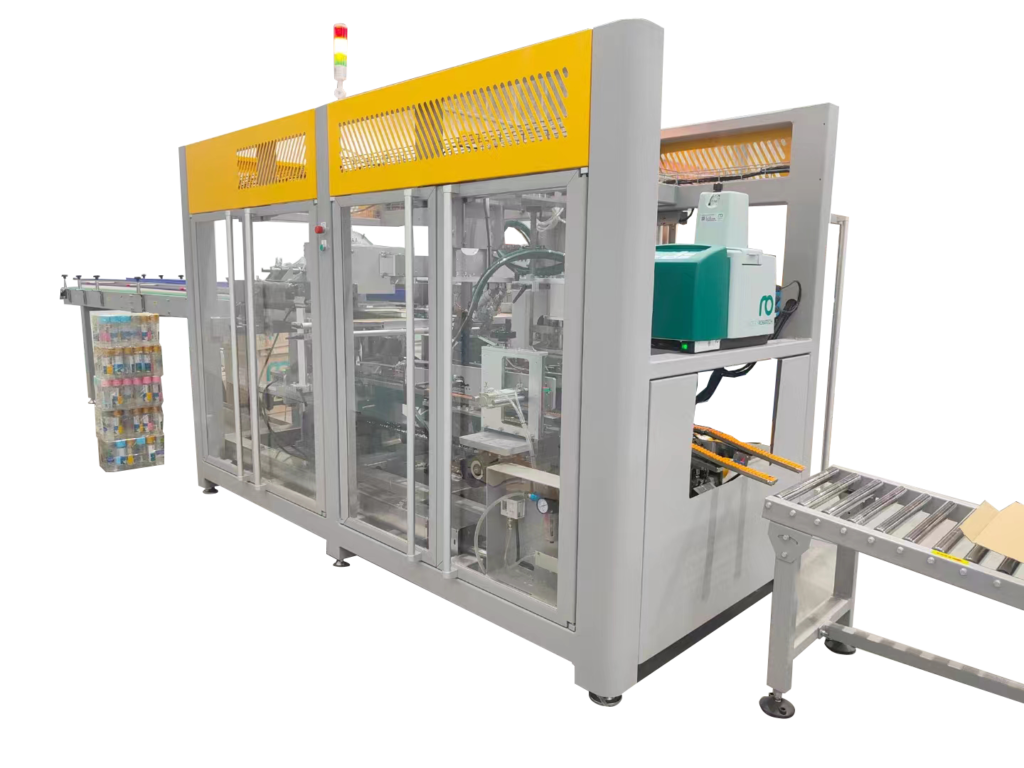

Overview of Automatic Wrap around case packer Machine

Basic definition

A wrap-around cartoning machine is a type of automated packaging equipment. Its core function is to use a single sheet of pre-scored corrugated cardboard (a one-piece blank) to automatically unpack, load the product, and fold and seal the bottom and lid to create a sturdy “wrap-around” carton.

This type of carton typically has multiple overlapping flaps sealed with hot melt adhesive, rather than the traditional tongue-type box.

Basic working principle

Its workflow is a highly coordinated, sequential, and automated process:

Case Removal and Unpacking: A vacuum suction cup picks up a flat blank from the hopper and precisely opens it into a rectangular cylindrical shape.

Blank Positioning: The opened blank is conveyed to the filling station, where the bottom flaps are typically initially opened and secured by a support mechanism.

Product Loading: Products (typically bottles, cans, bags, etc.) are loaded into the case by top drop, horizontal push, or robotic gripping.

Bottom Folding and Sealing: A robotic folding arm folds the bottom flaps in a pre-set sequence, sprays hot melt adhesive on the overlapping areas, and then presses them together to ensure a secure bond.

Case Turning: The bottom-sealed case is flipped 180°, with the opening facing upward, for top sealing.

Top Folding and Sealing: The process of folding, gluing/taping, and pressing is repeated to complete the top seal.

Product Output: The packaged case is conveyed out of the machine for the next stage (such as labeling or palletizing).

Watch Automatic Wrap around case packer in action

Main technical parameters

Parameter Category | Specific indicators | Description/Typical Range |

Production capacity | Packaging speed | 10 – 25 cases/minute (depending on product complexity and case type) |

Carton specifications |

Size range (L×W×H) | Minimum: e.g, 150×100×80mm |

Maximum: e.g., 600×500×500mm | ||

Cardboard material and weight | B/C, B/B and other corrugated types; 250 – 500 g/m² | |

Product adaptability | Product Type | Regular collections of objects such as bottles, cans, boxes, and bags |

Maximum load-bearing capacity | Typically ≤ 25 kg | |

Public resources | Gas source | 0.6-0.8 MPa, clean dry air, consumption ~500 L/min |

power supply | 380V / 50Hz / three-phase, total power 15-25 kW | |

Hot melt adhesive consumption | Depending on the speed and glue type, the equipment must indicate the maximum glue melting capacity (kg/h),generally5KG/10KG | |

Physical parameters | Equipment size | ~5000×2000×2000 mm (length×width×height) |

Equipment weight | ~3000 – 4000 kg |

Core components

Carton blank feeding system

silo, vacuum suction cup, and carton opening guide mechanism

Drive and transmission system

servo motor (mainstream), reducer, cam, connecting rod, belt/chain, providing precise power

Mechanical part

Complex folding arm and pressing mechanism

Sealing part

hot melt adhesive system (glue machine, glue hose, glue spray valve)

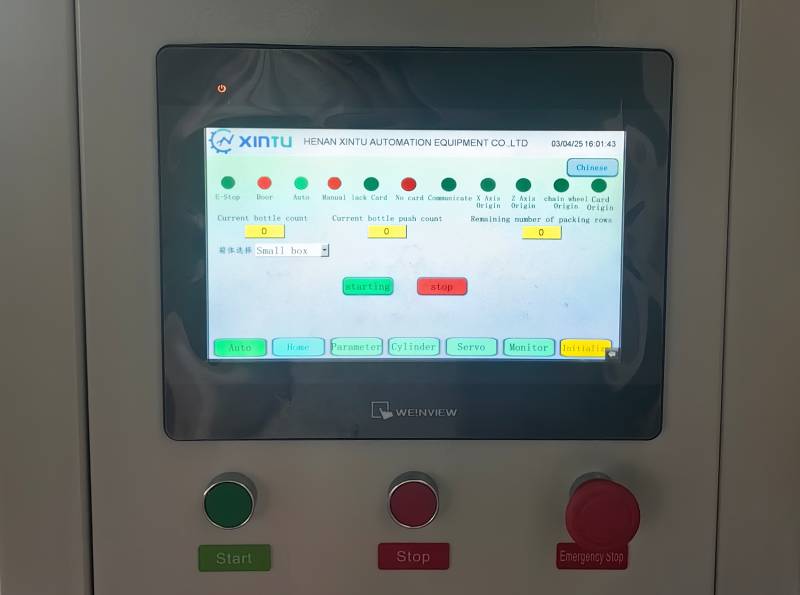

Control system:

PLC (Programmable Logic Controller, such as Siemens and Inovance), HMI (MCGS human-machine interactive touch screen), sensors (OMRON/Controlway photoelectric and proximity switches)

Frame and safety protection

solid steel structure, fully enclosed or semi-enclosed safety door, emergency stop button, safety light grid

Performance characteristics and advantages

- High Packaging Strength: The wrap-around construction ensures uniform load distribution on the bottom and lid of the box, significantly exceeding the weight-bearing and pressure-resistance of flap-type cartons, making it particularly suitable for heavy products and long-distance transportation.

- Excellent Displayability: The smooth sealing surface is ideal for branding and display on the top of the box, enhancing the product's image.

- High Automation and Efficiency: Fully automated, significantly reducing manual labor and ensuring a continuous and stable production pace.

- Excellent Flexibility: The servo system and H-interface interface enable rapid switching between different product sizes and box formats, minimizing changeover time.

- Efficient Packaging Materials: One-piece box blanks typically use 20% less paper than traditional box blanks.

Application Scenario

Wrap-around cartoning machines are widely used in industries requiring high-strength, high-quality packaging:

Beverage Industry: Whole-case packaging of beer, mineral water, and beverages.

Food Industry: Canned goods, cooking oil, condiments, and snack foods.

Daily Chemicals: Laundry detergent, shampoo, and cosmetics.

Chemical Industry: Paints, lubricants, and detergents.

Pharmaceutical Industry: Large infusion bottles and pharmaceutical packaging.

Selection considerations

- Product Characteristics: Size, weight, shape, and material (e.g., glass bottles, PET bottles).

- Productivity Requirements: Define current and future carton-per-minute requirements.

- Carton Types and Dimensions: Confirm that the equipment can handle all carton sizes you currently and plan to use in the future.

- Sealing Method: Hot melt adhesive (for high strength, aesthetics, and anti-counterfeiting).

- Integration and Compatibility: How does the equipment seamlessly integrate with upstream (cartoning machines, filling machines) and downstream (labeling machines, palletizers) equipment?

- Supplier Support: The supplier's technical expertise, after-sales service network, and speed of spare parts delivery are crucial, even more important than the equipment itself.

- Budget: Weigh the initial investment against long-term operating costs (consumables, efficiency, and maintenance).

Why Choose Us

15+ Years of Engineering Expertise

Global Sales & Support Network

Customized Solutions

Turnkey Project Management

Comprehensive After-sales Service

✅ Partner with XINTU – Smarter Packaging. Higher Efficiency. Lower Costs.

1. Proven Expertise in Packaging Automation

20+ years of industry experience in case packers, carton erectors, sealers, palletizers, stretch wrappers, labelers, and turnkey packaging lines.

A professional team of engineers and technicians dedicated to designing efficient, cost-effective, and stable systems.

2. Customized Solutions for Your Industry

Flexible design to fit bottles, bags, boxes, pouches, and specialty packaging.

Tailored automation lines for Food & Beverage, Daily Chemicals, Pharmaceuticals, Electronics & 3C, Hardware, E-commerce & Warehousing.

OEM/ODM customization to match your branding, compliance, and production needs.

3. Cost Savings & High ROI

Boost production efficiency by up to 300%.

Reduce labor dependency and operating costs.

Minimize downtime with stable, low-maintenance machines.

Accelerated return on investment through productivity gains.

4. Global Quality Standards

International certifications and compliance (CE, ISO, etc.).

High-quality components from trusted global suppliers.

Built to last with robust structure and advanced automation technology.

5. Seamless Integration & Smart Technology

Modular design for easy integration into existing lines.

Compatible with multiple communication protocols & software interfaces.

Options for remote monitoring, IoT, and smart control.

6. End-to-End Service & Support

Fast delivery and on-time project execution.

Technical training for your team.

24/7 after-sales service and spare parts support.

Global reach with support in North America, Europe, Asia, and beyond.

7. Trusted by Global Clients

Factories, trading companies, and system integrators across the U.S., Canada, Mexico, Europe, South America, Russia, Central Asia, Middle East, and Southeast Asia trust XINTU for reliable packaging automation.

We don’t just provide machines—we help you unlock efficiency, reduce costs, and future-proof your production.

Get a customized packaging solution

Fill Out The Enquiry Form And We Will Contact You Shortly

VIDEOS

Drop type Wrap Around Case Packer For bottled water

The XINTU Drop Type Wrap Around Case Packer is engineered for high-speed packing of bottled water, achieving speeds of up to 25 cases per minute. This versatile Drop Load Case Packer, also known as a Gravity Feed Case Packer or Vertical Drop Wrap Around Packer, ensures precise and consistent packaging. Ideal for the beverage industry, particularly for bottled water, this Automatic Wrap Around Packer handles various bottle sizes and shapes with ease. Its robust design and advanced features make it a top choice for optimizing your production line, ensuring efficiency and reliability.

Drop type Wrap Around Case Packer For jug motor oil

The XINTU Drop Type Wrap Around Case Packer, also known as a Drop Load Case Packer or Gravity Feed Case Packer, is optimized for high-speed packaging of jug motor oil, achieving speeds up to 25 cases per minute. This Automatic Wrap Around Packer is ideal for the automotive industry, offering precise and efficient packaging solutions for various jug sizes and shapes. With advanced features and robust design, the High-Speed Wrap Around Case Packer ensures reliable performance and minimal downtime, making it a preferred choice for vertical wrap around and top drop case packing applications.

Top Load Case Packer For bottled liquor

Enhance your production line with our Drop Load Case Packer for bottled liquor, packing 10-25 cartons per minute. Designed for the beverage industry, it handles various bottle sizes and shapes, ensuring consistent, high-volume packaging. Ideal for liquor, wine, and spirits, this machine guarantees efficient, reliable operation to meet your demanding production schedules.

LAYOUT DRAWINGS

Explore our extensive range of Packaging layout solutions tailored for your project needs.

Layout of Drop type wrap-around case packer

25 cases per minute case packer layout for beverage plants

FAQ

Listed below are the types of technical questions you may have about XINTU Drop Type Wrap Around case packing machine

Working Principles of XINTU Drop Type Wrap Around case packer

The XINTU Drop Type Wrap Around Case Packer, also known as a Drop Load Case Packer or Gravity Feed Case Packer, operates with high efficiency and precision. This automatic wrap around packer utilizes a vertical drop mechanism, where products are fed into the machine and then dropped into preformed wrap-around cases. The design of this vertical wrap around case packer ensures secure and stable packaging, which is crucial for maintaining product integrity during transportation.

Advanced features such as vision guidance and line tracking are also integrated into the system for some projects to correct product misalignment and maximize performance. As a high-speed wrap around case packer, it can achieve speeds of up to 25 cases per minute, making it ideal for various industries, including automotive and beverage. The flexibility of the top drop case packer allows it to handle different product sizes and shapes, enhancing the overall productivity and efficiency of your carton packing line.

By employing the vertical drop wrap around packer technology, XINTU ensures that your products are packaged reliably and efficiently, meeting the high standards of modern industrial packaging requirements.

Maintenance of Your XINTU Drop Type Wrap Around case packer

Proper maintenance of your XINTU Drop Type Case Packer ensures its longevity and optimal performance. The following guidelines help maintain your Wrap Around Case Packer, including Drop Load Case Packer and Vertical Wrap Around Case Packer models:

Routine Inspections

Regularly inspect your Automatic Wrap Around Packer for wear and tear. Check all moving parts, particularly those involved in the drop and wrap-around mechanism. Ensure that the Gravity Feed Case Packer components are free from obstructions and debris.

Lubrication

Lubricate the necessary parts of your High-Speed Wrap Around Case Packer to minimize friction and prevent mechanical failures. Follow the manufacturer’s guidelines for specific lubrication points on your Vertical Drop Wrap Around Packer.

Cleaning

Keep the Drop Pack Case Packer clean by removing any accumulated dirt, dust, or product residues. This helps maintain the efficiency of your Top Drop Case Packer and prevents contamination of packaged products.

Software Updates

Ensure that the control software for your Vertical Wrap Around Case Packer is up-to-date. Regular updates can enhance the performance and functionality of your case packing system.

Component Replacement

Replace any worn or damaged parts promptly. Using genuine XINTU parts ensures the continued reliability of your Drop Load Case Packer and maintains its operational standards.

Professional Servicing

Schedule regular professional servicing for your Drop Type Case Packer. Expert technicians can identify potential issues early and provide necessary repairs or adjustments to your Wrap Around Case Packer.

Adhering to these maintenance practices ensures that your XINTU Drop Type Wrap Around Case Packer continues to deliver high-speed, reliable, and efficient packaging solutions.

The XINTU Drop Type Case Packer integrates advanced technology to deliver efficient and reliable packaging solutions. This Drop Load Case Packer is engineered to handle a variety of packaging needs, making it a versatile addition to any production line. The Automatic Wrap Around Packer uses precision mechanics and state-of-the-art software to ensure seamless operations.

Key Technological Features:

High-Speed Operations The High-Speed Wrap Around Case Packer is designed to handle up to 25 cases per minute, ensuring high productivity and efficiency in packaging processes.

Versatile Packaging Options The Vertical Wrap Around Case Packer can accommodate different packaging formats, including gravity feed and drop pack configurations, making it suitable for diverse industry needs.

Precision and Consistency The Gravity Feed Case Packer employs advanced sensors and control systems to maintain consistent packing accuracy. This ensures minimal product waste and optimal packing quality.

Advanced Control Systems Equipped with PLC and touch screen controls, the Drop Pack Case Packer offers intuitive operation and easy troubleshooting. The control system allows for quick adjustments to pack different product sizes and shapes.

Robust Construction Built with durable materials, the Top Drop Case Packer is designed for long-term use in demanding industrial environments. The machine's robust frame and high-quality components ensure reliable performance.

Flexible Integration The Vertical Drop Wrap Around Packer can be seamlessly integrated into existing production lines, enhancing overall packaging efficiency. This feature makes it an ideal choice for expanding or upgrading packaging operations.

By leveraging the latest technology, the XINTU Drop Type Wrap Around Case Packer provides a reliable and efficient solution for your packaging needs, ensuring high-speed performance and adaptability across various applications.

Installing your XINTU Drop Type Case Packer is a streamlined process designed to ensure optimal performance and integration into your production line. Here's a step-by-step guide to the installation process, incorporating key features and benefits of our technology:

Preparation and Site Assessment

- Before installation, assess the site to ensure adequate space and proper infrastructure for the Drop Load Case Packer.

- Ensure power supply, air pressure, and other utilities meet the requirements for the Automatic Wrap Around Packer.

Machine Setup

- Position the High-Speed Wrap Around Case Packer in the designated area, ensuring stability and accessibility for operators.

- Align the Vertical Wrap Around Case Packer with existing conveyor systems and production lines for seamless integration.

Electrical and Pneumatic Connections

- Connect the Gravity Feed Case Packer to the power supply and pneumatic lines, following safety protocols and manufacturer guidelines.

- Verify all connections are secure and compliant with local electrical standards.

Calibration and Testing

- Perform initial calibration of the Drop Pack Case Packer, adjusting settings to match the specific product sizes and packaging requirements.

- Conduct thorough testing to ensure the Top Drop Case Packer operates efficiently and accurately, making any necessary adjustments.

Operator Training

- Provide comprehensive training for your staff on operating the Vertical Drop Wrap Around Packer, focusing on safety, maintenance, and troubleshooting.

- Utilize the intuitive control interface to familiarize operators with the machine's functionalities.

Final Inspection and Handover

- Conduct a final inspection of the installation, verifying all components of the Wrap Around Case Packer are functioning correctly.

- Officially hand over the machine, ensuring your team is confident in operating and maintaining the equipment.

By following these steps, you can ensure a smooth installation process for your XINTU Drop Type Wrap Around Case Packer, maximizing its efficiency and productivity in your packaging operations.

Yes, the XINTU Drop Type Wrap Around Case Packaging Machine is designed to handle different product sizes and shapes. Here are some features that make it versatile:

Adjustable Settings: The machine can be easily adjusted to accommodate a wide range of product dimensions, ensuring it can pack various sizes and shapes efficiently.

Flexible Configuration: Its design includes customizable modules that can be tailored to the specific needs of different products, enhancing its adaptability.

Automatic Adjustment: Equipped with advanced sensors and control systems, the machine can automatically adjust its settings to handle different product sizes and shapes seamlessly, maintaining high-speed and accurate packing.

These capabilities ensure that the Drop Type Wrap Around Case Packer can effectively manage a diverse array of products, making it a highly versatile solution for your packaging needs.

The XINTU Drop Type Wrap Around Case Packer boasts several key features that make it a versatile and efficient solution for your packaging needs:

High-Speed Operations

- The High-Speed Wrap Around Case Packer can process up to 25 cases per minute, ensuring rapid and efficient packaging.

Versatile Packaging

- The Drop Load Case Packer and Vertical Wrap Around Case Packer accommodate various product sizes and shapes, offering flexible packaging solutions.

Automated Precision

- The Automatic Wrap Around Packer guarantees precise and consistent packaging, minimizing errors and material waste.

Advanced Integration

- The Gravity Feed Case Packer and Top Drop Case Packer seamlessly integrate with existing production lines, enhancing overall efficiency.

Space Optimization

- The Vertical Drop Wrap Around Packer optimizes space within your facility, making the best use of available floor space.

Reliable Performance

- The Drop Pack Case Packer is designed for high reliability and minimal downtime, ensuring consistent and dependable performance.

By incorporating these features, the XINTU Drop Type Wrap Around Case Packer provides a comprehensive and efficient solution for a wide range of packaging applications.

Ensuring consistent packing with the XINTU Drop Type Wrap Around Case Packer involves leveraging its advanced features and technologies:

Automated Precision

- The Automatic Wrap Around Packer utilizes precise control mechanisms to ensure each product is accurately positioned and securely packed.

High-Speed Efficiency

- The High-Speed Wrap Around Case Packer is designed to maintain high throughput while ensuring each case is packed consistently, minimizing variations and errors.

Versatile Handling

- The Drop Load Case Packer and Vertical Wrap Around Case Packer are capable of handling a variety of product sizes and shapes, adjusting seamlessly to ensure uniform packing.

Gravity Feed Mechanism

- The Gravity Feed Case Packer uses gravity to guide products into cases smoothly, reducing the risk of misalignment and ensuring each product is correctly placed.

Robust Construction

- The Top Drop Case Packer and Vertical Drop Wrap Around Packer are built with durable materials and designed for stability, ensuring reliable operation even in high-speed applications.

Advanced Control Systems

- The Drop Pack Case Packer features sophisticated PLC and touch screen controls that monitor and adjust the packing process in real-time, maintaining consistency across all operations.

By incorporating these advanced features, the XINTU Drop Type Wrap Around Case Packer ensures reliable and consistent packing, enhancing your overall packaging efficiency and product quality.

Integrating the XINTU Drop Type Wrap Around Case Packer with your current production line can be a seamless process:

Automation Compatibility

- The Drop Type Case Packer is designed for easy integration into automated systems, ensuring smooth operations with existing equipment.

Versatile Integration

- The Wrap Around Case Packer and Vertical Wrap Around Case Packer offer versatile compatibility with various production line setups, allowing for straightforward implementation.

High-Speed Performance

- With the High-Speed Wrap Around Case Packer, you can maintain or increase your production speed, ensuring that the integration does not slow down your line.

Flexibility in Product Handling

- The Drop Load Case Packer and Drop Pack Case Packer can handle different product sizes and shapes, providing flexibility and efficiency in your production line.

Advanced Control Systems

- Equipped with sophisticated PLC controls, the Automatic Wrap Around Packer offers precise synchronization with your existing machinery, ensuring optimal performance.

Space Efficiency

- The Top Drop Case Packer and Vertical Drop Wrap Around Packer are designed to fit into compact spaces, making them suitable for production lines with space constraints.

Smooth Operation

- The Gravity Feed Case Packer ensures reliable product handling, reducing the risk of jams and ensuring consistent operation throughout the production line.

By utilizing these advanced features, the XINTU Drop Type Wrap Around Case Packer integrates efficiently into your existing production line, enhancing productivity and ensuring consistent, high-quality packing.

The energy requirements for operating the XINTU Drop Type Wrap Around Case Packer are designed to ensure efficient and reliable performance. Here are the key details:

- Power Supply: The Drop Type Case Packer and Wrap Around Case Packer models typically require a three-phase power supply, operating at 380V and 50/60Hz.

- Power Consumption: These machines, including the Drop Load Case Packer and Automatic Wrap Around Packer, consume approximately 10KW of power, ensuring high-speed operation and efficiency.

- Air Pressure: The High-Speed Wrap Around Case Packer and Vertical Wrap Around Case Packer require an air pressure range of 0.5 to 0.7 MPA to function optimally.

- Operational Efficiency: The Gravity Feed Case Packer and Drop Pack Case Packer are designed to minimize energy waste, making them both eco-friendly and cost-effective.

- Advanced Features: Incorporating features such as high-speed operation, these Top Drop Case Packer and Vertical Drop Wrap Around Packer models are built to handle various packaging needs efficiently.

By meeting these energy requirements, the XINTU Drop Type Wrap Around Case Packer ensures robust performance, catering to diverse industrial needs while maintaining energy efficiency.

The XINTU Drop Type Wrap Around Case Packer incorporates several advanced safety features to ensure reliable and secure operation. These features are designed to protect both the operator and the equipment, while maintaining optimal performance. Here are the key safety features:

Emergency Stop Systems: The Drop Type Case Packer and Wrap Around Case Packer are equipped with strategically placed emergency stop buttons, allowing operators to halt the machine instantly in case of an emergency.

Safety Guarding: All Drop Load Case Packer and Automatic Wrap Around Packer models come with robust safety guards that prevent access to moving parts during operation, ensuring operator safety.

Non-Contact Interlocks: The High-Speed Wrap Around Case Packer and Vertical Wrap Around Case Packer utilize non-contact interlocks to ensure that the machine only operates when all safety guards are securely in place.

CAT-3 Safety Circuits: The Gravity Feed Case Packer and Drop Pack Case Packer are designed with CAT-3 safety circuits, which provide a high level of safety integrity and redundancy.

Grace Ports: The Top Drop Case Packer and Vertical Drop Wrap Around Packer feature easily accessible grace ports that allow for safe access to the machine for maintenance without compromising safety.

Vision Systems: These systems ensure that the Wrap Around Case Packer operates correctly, checking for product alignment and packaging integrity, and shutting down the machine if an issue is detected.

By integrating these comprehensive safety features, the XINTU Drop Type Wrap Around Case Packer ensures a safe working environment, minimizing risks and maximizing operational efficiency.

Selecting the appropriate Drop Type Wrap Around Case Packer for your packaging operations involves considering several key factors. Here’s how you can choose the best fit for your needs:

Product Specifications:

- Evaluate the size, shape, and material of your products. Different models of Drop Type Case Packer, Wrap Around Case Packer, and Drop Load Case Packer are optimized for specific product dimensions and types, such as bottles, cans, or pouches.

Speed and Efficiency:

- Determine the required throughput for your production line. If high-speed operation is crucial, opt for a High-Speed Wrap Around Case Packer. Models like the Automatic Wrap Around Packer and Vertical Wrap Around Case Packer offer varying speeds to match your production demands.

Packaging Format:

- Consider the packaging style you need. The Gravity Feed Case Packer and Drop Pack Case Packer are suitable for different case formats, whether you require a Top Drop Case Packer or a Vertical Drop Wrap Around Packer.

Integration with Existing Systems:

- Assess how well the new equipment will integrate with your current production line. Look for models that can seamlessly connect with your existing setup to ensure smooth operations without extensive modifications.

Flexibility and Versatility:

- If your packaging needs are diverse, select a model with high versatility. The Drop Type Wrap Around Case Packer and Wrap Around Case Packer models offer flexibility in handling various products and packaging configurations, providing a comprehensive solution for different requirements.

Budget Considerations:

- Align your choice with your budget constraints. Evaluate the cost-effectiveness of the Drop Load Case Packer and the Automatic Wrap Around Packer options, ensuring you get the best value for your investment.

By thoroughly analyzing these factors, you can choose the most suitable Drop Type Wrap Around Case Packer for your packaging needs, ensuring efficiency, reliability, and optimal performance in your production line.

There are several types of Drop Type Wrap Around Case Packing Machines designed to cater to different packaging needs:

- Drop Type Case Packer: Designed for straightforward drop-in packing applications, handling various product sizes efficiently.

- Wrap Around Case Packer: Ideal for forming and sealing wrap-around cases for products, ensuring a secure and aesthetic package.

- Drop Load Case Packer: Specializes in drop-loading products into cases, perfect for heavy or bulk items.

- Automatic Wrap Around Packer: Automates the entire wrap-around packaging process, boosting efficiency and reducing labor costs.

- High-Speed Wrap Around Case Packer: Optimized for high-speed operations, capable of packing at exceptional speeds without compromising accuracy.

- Vertical Wrap Around Case Packer: Utilizes vertical loading to accommodate various product shapes, ensuring stability during the packaging process.

- Gravity Feed Case Packer: Uses gravity to feed products into the packing area, suitable for delicate or lightweight items.

- Drop Pack Case Packer: Focuses on dropping products into cases, perfect for a wide range of product sizes and shapes.

- Top Drop Case Packer: Incorporates top-loading mechanisms for efficient and versatile packaging solutions.

- Vertical Drop Wrap Around Packer: Combines vertical drop and wrap-around features to handle diverse packaging requirements.

These various types of case packers ensure that you can find the perfect machine for your specific packaging needs, enhancing productivity and maintaining high standards of packaging quality.

Utilizing the XINTU Drop Type Wrap Around Case Packer offers numerous efficiency benefits that can significantly enhance your packaging operations:

High-Speed Operations: The High-Speed Wrap Around Case Packer can handle up to 25 cases per minute, ensuring rapid throughput and increased productivity.

Versatile Packaging Solutions: This machine, including models like the Drop Load Case Packer and Vertical Wrap Around Case Packer, accommodates various product sizes and shapes, providing flexibility for diverse packaging needs.

Automated Precision: The Automatic Wrap Around Packer ensures precise and consistent packaging, reducing errors and minimizing material wastage.

Efficient Space Utilization: Models like the Gravity Feed Case Packer and Top Drop Case Packer optimize space within the packaging line, ensuring efficient use of factory floor space.

Advanced Technology Integration: The Vertical Drop Wrap Around Packer incorporates advanced technology for seamless integration into existing production lines, enhancing overall system efficiency.

By integrating these features, the XINTU Drop Pack Case Packer ensures that your packaging process is streamlined, cost-effective, and capable of handling high-volume demands with ease.

The XINTU Drop Type Wrap Around Case Packer comes in various models, each tailored for specific production needs and capabilities:

Standard Drop Type Case Packer

- Capacity: Up to 20-25 cases per minute

- Features: Versatile for various product sizes and shapes

High-Speed Wrap Around Case Packer

- Capacity: Up to 30-35 cases per minute

- Features: Optimized for high-speed operations with advanced automation

Vertical Wrap Around Case Packer

- Capacity: Up to 25-30 cases per minute

- Features: Ideal for vertical packing configurations and efficient space utilization

Automatic Wrap Around Packer

- Capacity: Up to 25 cases per minute

- Features: Fully automated with minimal manual intervention required

Drop Load Case Packer

- Capacity: Up to 20 cases per minute

- Features: Reliable and efficient for drop load applications

Gravity Feed Case Packer

- Capacity: Up to 20 cases per minute

- Features: Utilizes gravity for product feeding, reducing mechanical complexity

Top Drop Case Packer

- Capacity: Up to 22 cases per minute

- Features: Designed for top loading, ensuring product integrity

Vertical Drop Wrap Around Packer

- Capacity: Up to 25 cases per minute

- Features: Vertical drop mechanism for smooth and consistent packing

By selecting the appropriate model, you can optimize your production line with the right balance of speed, efficiency, and flexibility using XINTU's advanced Drop Type Case Packers, Wrap Around Case Packers, and High-Speed Wrap Around Case Packers.

To maximize the efficiency of your Drop Type Case Packer, Wrap Around Case Packer, and other related machines, follow these key strategies:

Regular Maintenance: Consistently maintain your Drop Load Case Packer and Gravity Feed Case Packer to prevent downtime and ensure smooth operations. Scheduled inspections and servicing keep your equipment running optimally.

Operator Training: Ensure your staff is thoroughly trained on the Automatic Wrap Around Packer and High-Speed Wrap Around Case Packer. Well-trained operators can handle minor issues swiftly, reducing delays.

Automation Integration: Utilize advanced automation features in your Vertical Wrap Around Case Packer and Drop Pack Case Packer. Automation reduces manual intervention, improving speed and accuracy.

Efficient Changeovers: Implement quick-changeover techniques for your Top Drop Case Packer and Vertical Drop Wrap Around Packer. Fast changeovers minimize downtime and maintain high productivity levels.

Optimize Product Flow: Ensure a consistent and smooth product flow into the Drop Type Wrap Around Case Packer. Properly configured conveyors and feeders improve efficiency and reduce bottlenecks.

Use Quality Materials: Employ high-quality materials and components in your Drop Load Case Packer and Wrap Around Case Packer to reduce wear and tear, extending machine lifespan and maintaining efficiency.

By implementing these strategies, you can significantly enhance the performance and efficiency of your Drop Type Case Packer, Automatic Wrap Around Packer, and other related machines, ensuring a seamless and productive packaging process.

When working with Drop Type Case Packers, Wrap Around Case Packers, and similar equipment, you may encounter a few common issues. Here’s how to identify and troubleshoot them:

Misalignment of Products: This is a frequent issue with Drop Load Case Packers and Gravity Feed Case Packers.

- Troubleshooting: Check and adjust the alignment settings, ensure the conveyors are properly aligned, and inspect the sensors for any blockages or misconfigurations.

Inconsistent Sealing: Problems with sealing can occur in Automatic Wrap Around Packers and High-Speed Wrap Around Case Packers.

- Troubleshooting: Inspect the sealing components for wear and tear, adjust the temperature settings, and ensure that the heat sources are uniformly heating.

Jamming: Jamming can be a significant issue in Vertical Wrap Around Case Packers and Drop Pack Case Packers.

- Troubleshooting: Regularly clean the machine to prevent debris buildup, check for any misaligned parts, and ensure that the products being packed meet the specified dimensions and weights.

Speed Fluctuations: Speed inconsistencies can affect Top Drop Case Packers and Vertical Drop Wrap Around Packers.

- Troubleshooting: Verify the machine’s speed settings, inspect the motor and drive systems, and check for any obstructions in the product flow that might be causing slowdowns.

Faulty Ejectors: This can happen in any Drop Type Case Packer model.

- Troubleshooting: Ensure that the ejector mechanisms are properly lubricated, check for any mechanical obstructions, and calibrate the ejectors to function correctly.

By regularly maintaining your Wrap Around Case Packer and following these troubleshooting steps, you can minimize downtime and maintain optimal performance of your packaging system.

Ensuring the safe and efficient operation of a Drop Type Wrap Around Case Packer involves thorough training. Here's how to effectively train your staff:

Comprehensive Training Program:

- Develop a detailed training program that covers all aspects of operating the Drop Type Case Packer, Wrap Around Case Packer, and Drop Load Case Packer. This should include initial setup, regular operation, and emergency procedures.

Step-by-Step Instruction:

- Provide clear, step-by-step instructions on how to use the Automatic Wrap Around Packer and the High-Speed Wrap Around Case Packer. Include visual aids and hands-on demonstrations to enhance understanding.

Safety Protocols:

- Emphasize the importance of safety protocols specific to the Vertical Wrap Around Case Packer, Gravity Feed Case Packer, and Drop Pack Case Packer. Train staff on how to handle equipment safely to prevent accidents and injuries.

Regular Refresher Courses:

- Conduct regular refresher courses to keep staff updated on the latest safety standards and operational techniques for the Top Drop Case Packer and Vertical Drop Wrap Around Packer. This ensures continuous improvement and adherence to best practices.

Use of Protective Gear:

- Instruct staff on the necessity of wearing appropriate protective gear when operating the Drop Type Wrap Around Case Packer. This includes gloves, safety glasses, and other necessary equipment to ensure personal safety.

Monitoring and Supervision:

- Implement a system for monitoring and supervising the operation of the Wrap Around Case Packer. This helps in identifying any potential issues early and addressing them before they escalate.

By following these training steps, you can ensure that your staff is well-equipped to operate the Drop Type Wrap Around Case Packer safely and efficiently, contributing to a productive and accident-free work environment.

The Drop Type Wrap Around Case Packer has seen significant technological advancements to enhance its efficiency and flexibility. Here are some of the latest innovations:

Advanced Automation:

- Modern Drop Type Case Packers and Wrap Around Case Packers now incorporate sophisticated automation technologies. These include Automatic Wrap Around Packers and Drop Load Case Packers which optimize the packing process by reducing manual intervention and increasing throughput.

High-Speed Capabilities:

- High-Speed Wrap Around Case Packers are designed to meet the demands of fast-paced production environments. They can handle higher speeds without compromising on accuracy or quality, making them ideal for industries that require rapid packaging solutions.

Versatile Configurations:

- The flexibility of Vertical Wrap Around Case Packers and Gravity Feed Case Packers allows them to adapt to different product sizes and shapes. This versatility ensures that the packers can handle a variety of packaging requirements with ease.

Enhanced Safety Features:

- Safety is paramount in the latest Drop Pack Case Packers and Top Drop Case Packers. Innovations include better safety interlocks, emergency stop features, and enhanced guarding to protect operators.

Precision and Accuracy:

- With the integration of advanced sensors and vision systems, Vertical Drop Wrap Around Packers ensure precise product placement and alignment. This technology minimizes errors and improves the overall packing quality.

Energy Efficiency:

- Newer models are designed to be more energy-efficient, reducing operational costs while maintaining high performance. This includes optimized motors and better control systems in Wrap Around Case Packers.

These advancements make the Drop Type Wrap Around Case Packer a robust and versatile solution for various packaging needs, offering improved efficiency, safety, and adaptability to modern production lines.