1. Introduction: The Bottleneck at the End of the Line

For Onega, a mid-sized food manufacturer running continuous day and night shifts, the end of the packaging line was a source of constant frustration and risk. Manual palletizing wasn't just a bottleneck; it was a business liability.

- Throughput was capped by human fatigue, limiting overall production capacity.

- Ergonomic injuries loomed large with operators manually handling cartons weighing up to 40kg.

- Inconsistent pallet patterns led to unstable loads, downstream delays, and product damage.

- The high cost and challenge of recruiting and retaining staff for repetitive, strenuous 24/7 shifts was unsustainable.

Their goal was clear: break the bottleneck, eliminate the risk, and boost efficiency—all without expanding their footprint or adding shifts. Their solution? A collaborative robot (cobot) palletizing system from XINTU Automation.

2. Why a Cobot Was the Right Tool for the Job

raditional industrial robots often require massive cages and extensive facility reworks. For [Client Name], the flexibility and safety of a cobot palletizer made it the perfect choice. Cobots are designed to work alongside humans, feature advanced force-sensing technology, and have a minimal footprint—ideal for retrofitting into existing lines with space constraints.

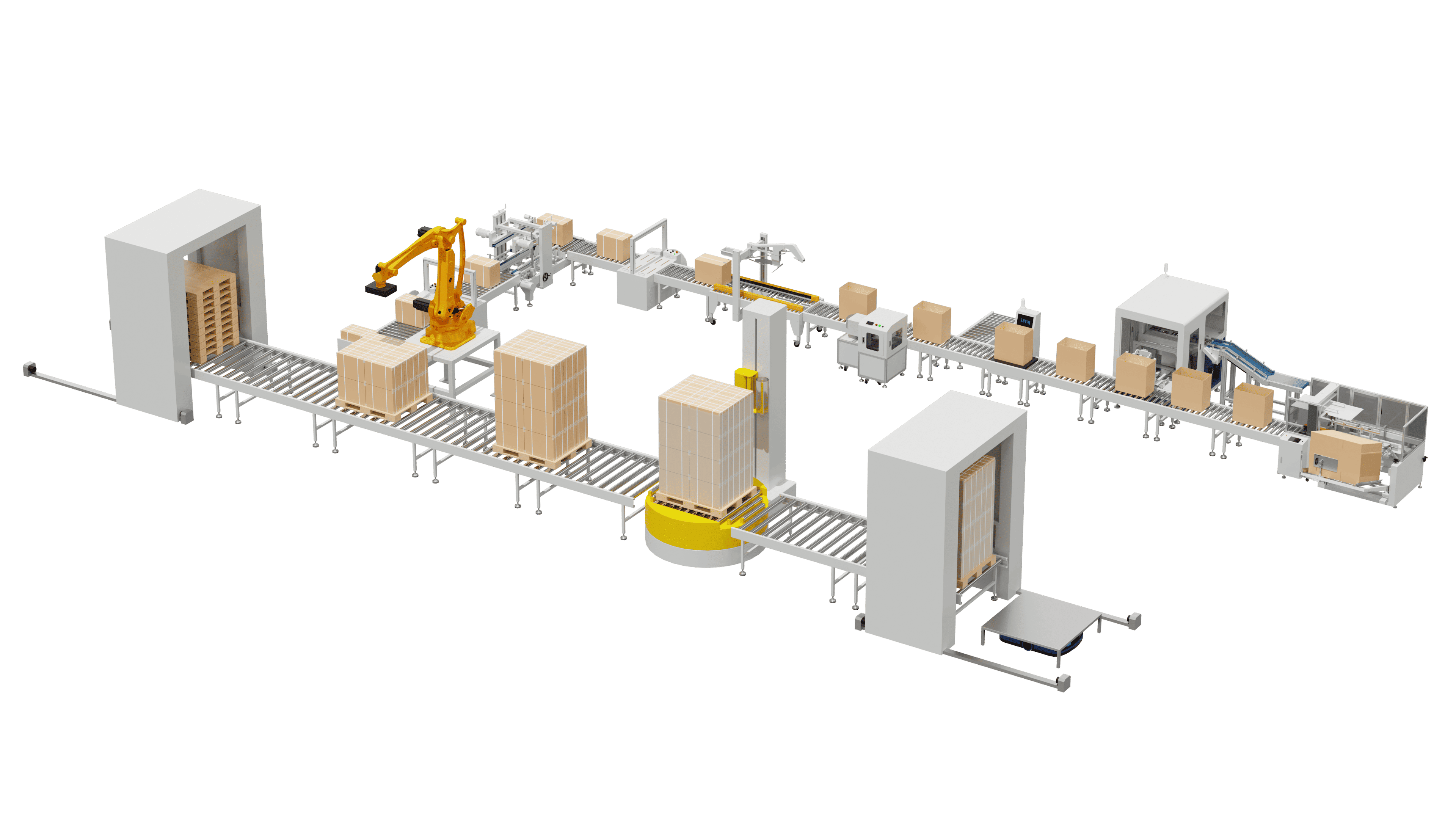

3. Our Solution: A Tailored Cobot Palletizing Cell

XINTU Automation conducted a thorough site audit and delivered a complete, integrated solution:

- A High-Payload Collaborative Robot: Selected for its strength, reach, and built-in safety features.

- Advanced End-of-Arm Tooling (EOAT): A custom-engineered gripper designed to handle their specific box types securely and gently.

- Integrated Vision System: Ensured precise pick-up and placement, even with minor variations in box placement.

- Intuitive Software: Allowed the client's team to create and switch between pallet patterns in minutes, providing incredible flexibility for different SKUs and orders.

Key Operational Envelope:

- Throughput: 8-12 cartons per minute (consistent)

- Box Weight Range: 10-40 kg

- Max Pallet Height: 2.3 m

Goals

The customer asked for a pragmatic solution that would:

- remove staff from repetitive heavy lifting and reduce injury risk;

- double palletizing throughput to match upstream packaging equipment;

- deliver a compact solution that integrates quickly with existing conveyors;

- show a fast, defensible ROI.

The solution: a collaborative robot palletizing cell

Rather than a large caged industrial cell, we implemented a cobot palletizer cell that balanced speed, safety and footprint:

Core components

- a high-payload collaborative robot arm with force sensing and safe stop behavior;

- an end-of-arm tool (EOAT) tailored to the client’s cartons (mechanical vacuum hybrid gripper);

- a pallet dispenser and pallet outfeed conveyor;

- recipe/pattern management software for rapid pallet pattern changes;

- PLC and I/O integration with upstream conveyors and line controls.

Why a cobot?

Cobots provide a nimble automation option with safety features that allow operation near people and minimal guarding, small floor footprint and fast programming for recipe changes — ideal for mid-volume lines and mixed SKUs.

Implementation: Seamless Integration with Minimal Disruption

Timeline: typical delivery and commissioning window 6–12 weeks depending on site readiness.

Key steps

- Site survey & line study — mapped conveyor speeds, bottle/case flow, available footprint, electrical and air.

- Layout design — located cobot, pallet dispenser, infeed smoothing and full pallet outfeed.

- Tooling design — custom gripper to accommodate box sizes, weights and surface finishes.

- Integration — PLC signals for line run/stop, pallet present, full pallet and interlocks.

- Programming & validation — teach pendant recipe creation, collision testing, speed tuning, and run rate validation.

- Training & handover — brief operator and maintenance training and supply of spare parts list.

- Post-go-live support — remote monitoring and performance tuning in first 2–4 weeks.

Measured results (customer data)

| Metric | Before (Manual) | After (Cobot) | Outcome |

|---|---|---|---|

| Throughput | ~6–8 cartons/min | 8–12 cartons/min | ~+100% effective palletizing capacity |

| Labor | 4 palletizers on shifts | 0 direct palletizers; staff redeployed | 4 FTEs freed |

| Box weight range | up to 10–40 kg | up to 10–40 kg handled | consistent handling |

| Pallet height | n/a variable | up to 2.3 m achieved | stable, repeatable stacks |

| Safety incidents | recorded cases annually | zero recordables during observation period | major reduction |

| Pallet quality | inconsistent | repeatable, square patterns | fewer downstream stoppages |

Business impact and ROI

Direct benefits

- Lower labor expense — redeployed staff into higher value roles (quality control, line supervision).

- Reduced injury and absenteeism costs — lower claims and improved workforce morale.

- Improved OEE — fewer line stoppages and smoother downstream handoff to shrinkwrap and palletizers.

- Smaller footprint vs large robotic cells — saves plant floor area.

ROI modelling (example approach)

- Annual labor saving = number of FTE removed × loaded annual cost per FTE.

- Annual indirect savings = reduced injury claims, reduced rework, lower downtime.

- Annual benefit = labor saving + indirect savings.

- Payback months = system CAPEX ÷ (annual benefit / 12).

Industry examples show payback windows vary by case but can be rapid for food and beverage lines — many customers report ROI within months to a year depending on labor rates and throughput gains.

Technical considerations and best practices

- Confirm payload & reach: match cobot model to your heaviest carton and stacking height. Cobots excel in small- to mid-payload applications; for very heavy continuous stacks consider an industrial robot.

- Gripper selection is critical: test EOAT designs early — mechanical fingers, vacuum, or hybrid solutions may be required depending on box rigidity and surface.

- Pallet recipe management: use recipe software to predefine patterns and reduce changeover time.

- Conveyor buffering: steady infeed avoids cobot starvation; include accumulation conveyors where needed.

- Safety & risk assessment: perform a full risk assessment and configure cobot safe zones and speed-reduction behaviors in accordance with local standards.

- Maintenance plan: simple preventive checks on gripper, vacuum lines, and joint lubrication keep MTTR low.

Common FAQs

Q: Can a cobot handle boxes up to 40 kg?

A: Some cobot models can handle higher payloads but check the specific model’s rated payload and reach. For heavier continuous duty, an industrial palletizing robot may be more appropriate.

Q: How disruptive is commissioning?

A: With a prepared site and clear conveyor handoffs, commissioning is typically completed within days to a few weeks. Full project timelines from order to production usually fall in the 6–12 week range.

Q: Are cobots safe to use around people?

A: Yes. Cobots include force sensing and safe stop algorithms; integrated safety measures and risk assessments are still required. Many deployments avoid large fences, enabling collaborative workflows.

Conclusion — the double win: productivity and safety

This case shows how collaborative automation can deliver both measurable productivity gains and meaningful safety improvements. The strongest outcomes come when a solution is specified to the product, integrated thoughtfully into the line, and accompanied by operator training so teams can adopt higher-value roles.

If palletizing is your bottleneck, cobot palletizing is a compelling, low-footprint option to increase throughput, reduce ergonomic risk and accelerate ROI. Industry evidence supports cobots as a practical choice for many food, beverage, pharmaceutical and consumer goods lines.

Next steps — how XINTU can help

We offer:

- free line assessment and feasibility check;

- tailored layout and pallet pattern proposal;

- a detailed ROI estimate based on your labor costs and volume;

- live or remote demo scheduling.

Contact

📧 Mary@xintuequipment.com

🌐 https://xintuequipment.com/

📲 WhatsApp / WeChat / Telegram: +86 151 3616 4937